Client Overview:

A leading industry player in outdoor power solutions required the design and development of a high-performance PoE Injector that adhered to the stringent IEEE 802.3bt standard. The device needed to support up to 90W of power delivery while maintaining operational integrity across a wide temperature range, all without relying on active cooling mechanisms. The primary challenge was to engineer a solution capable of meeting these demanding specifications while ensuring reliability and efficiency in harsh environmental conditions.

Solution by Electrobit:

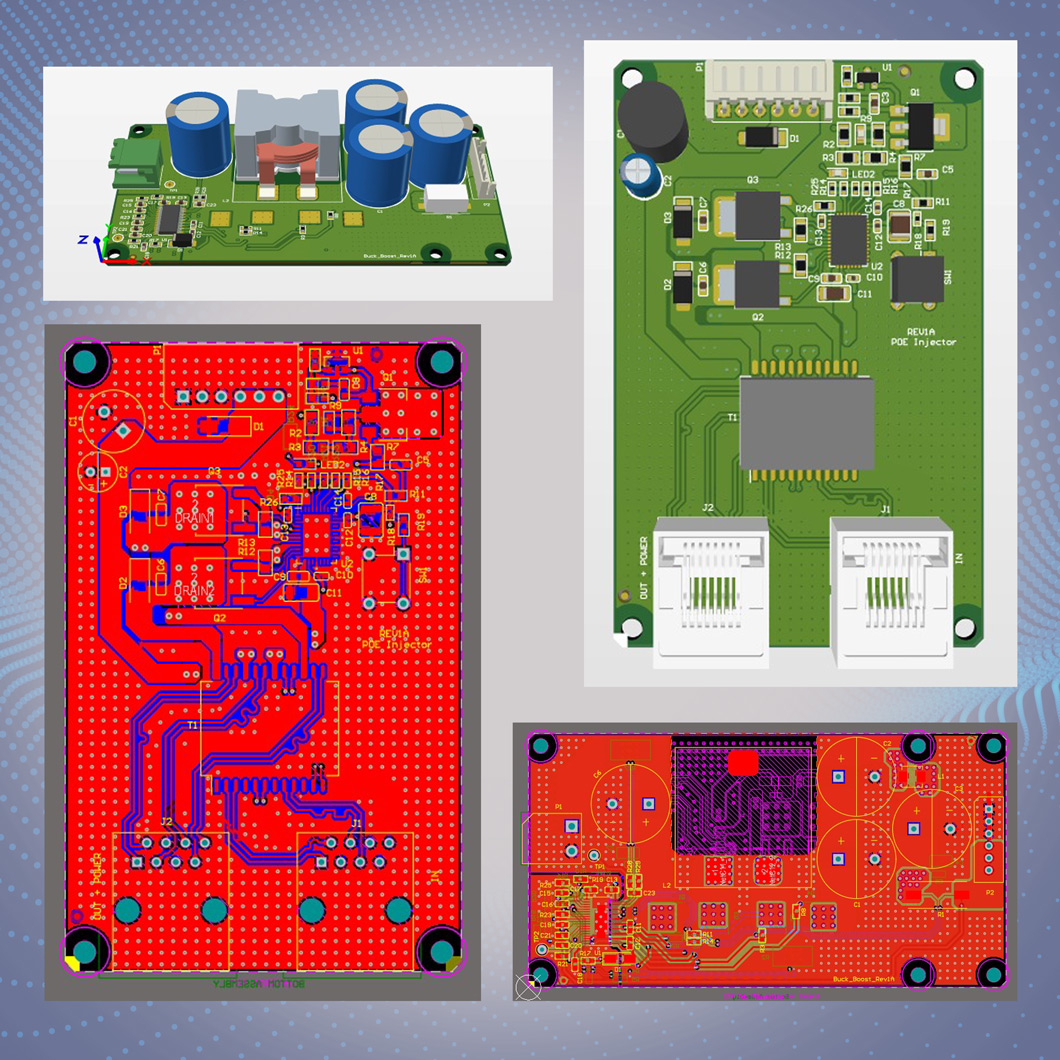

Electrobit was commissioned to design an innovative PoE Injector, addressing the client’s requirements for both hardware and firmware development. The project entailed creating a single-port, multi-gigabit PoE++ Injector with comprehensive protection features, dynamic status indicators, and adherence to rigorous industrial temperature standards.

![Industrial-IOT-1[1]](https://electrobittech.com/wp-content/uploads/2024/02/Industrial-IOT-11.jpg)